Gessner Offers a Suite of Filtration Solutions

GESSNER is the filtration solution provider for the most complex customer challenges, combining the know-how and expertise of former SWM & Neenah.

GESSNER is dedicated to solving intricate filtration problems, using its expertise and cutting-edge technology to address unique customer needs. In every aspect, GESSNER exemplifies a commitment to excellence, innovation, and sustainable practices, truly embodying the role of a leader in the filtration industry.

As a trusted partner in the filtration industry, GESSNER takes pride in its mission to protect people, machineries, and the environment. With our product portfolio, including high-quality filter media, pleat supports, cores, sleeves, and tubes GESSNER is dedicated to creating a better, cleaner, and healthier world. These advanced filtration solutions not only safeguard human health and prolong machinery lifespan but also play a vital role in environmental protection. By reducing harmful emissions and pollutants, GESSNER’s products contribute significantly towards a sustainable future, reinforcing their commitment to quality, safety, and ecological responsibility. See Gessner in Stand No. 208 to learn more about their nonwovens, media, and film products. Or email gessner@mativ.com or visit their website www.gessner-filtration.com.

Pleat support for filter elements – explore our Naltex™ diamond netting solutions: Naltex™ diamond nettings play a critical role as pleat support for filter elements. These extruded nettings are designed to maintain the shape and integrity of filter elements under high-pressure or corrosive conditions, which is essential for their optimal performance. The bi-planar structure of our Naltex™ nettings provide robust support, preventing the filter media from collapsing or deforming during operation.

Naltex™ nettings offer increased surface area due to their pleated design, enhancing the filtration capacity of the filter elements. They are also used as feed spacers in spiral wound water filtration membrane elements for various filtration processes, including Reverse Osmosis, Nano, Ultra, and Micro Filtration. This demonstrates the versatility and efficiency of Naltex™ diamond nettings in diverse filtration applications.

The key function of Naltex™ diamond nettings lies in their ability to provide effective pleat support, ensuring the durability, stability, and efficiency of filter elements across different industries and applications.

Naltex™ diamond nettings, renowned for their robust characteristics, are designed to withstand extreme temperatures, harsh chemicals, and abrasion, ensuring their durability in diverse environments. They play a pivotal role in providing maximum filtration efficiency due to their unique design and material composition.

Despite their lightweight construction, these nettings enable larger surface areas without any compromise on strength or durability. This is a significant advantage as it allows for higher filtration capacity without additional weight, making them more efficient and easy to handle.

These nettings also serve as a reliable support structure in applications, maintaining the integrity of the filter media under varying operational conditions. An added layer of protection ensures optimum performance by preventing clogging or blockage within the filter. This feature is crucial in maintaining consistent filtration quality over time.

Lastly, the use of Naltex™ diamond nettings can lead to reduced costs associated with waste removal and product contamination. By enhancing the filter's performance and longevity, they help lower maintenance expenses and prevent costly contamination issues, offering an economically efficient solution for various filtration needs.

Pleat support for filter elements – Delnet™ apertured films provide purity, high-strength, and non-stick properties: Delnet™ apertured films play a pivotal role as pleat supports in filtration systems, offering purity, high-strength, and non-stick properties.

Their key function lies in their capability to provide robust support to the filter elements, ensuring that they retain their shape and functionality even under strenuous conditions. This is vital in maintaining optimal filtration efficiency and preventing the collapse or deformation of the filter media during operation.

One of the defining features of Delnet™ apertured films is their purity. They do not contribute contaminants to the system, thereby improving the overall quality of filtration. Their high-strength properties further enhance their durability, making them an ideal choice for demanding applications.

Moreover, these apertured films possess non-stick properties, which help prevent clogging or blockage within the filter, ensuring smooth and efficient operation. This, in turn, reduces maintenance requirements and extends the lifespan of the filter elements.

Delnet™ apertured films serve as a reliable and efficient pleat support in filtration systems, providing purity, high strength, and non-stick properties.

GESSNER®´s high efficient filter media for high-end engine air applications: GESSNER is a leading provider of a diverse range of engine air filter media, meticulously designed to withstand the harshest global environments. Our technology ensures resilience and reliability, with our paper-meltblown combinations specifically engineered for high-end applications.

We also offer unique resin systems that deliver exceptional stiffness in both dry and wet conditions, providing resistance against water and temperature fluctuations. This feature allows quick drying of the media to prevent filter collapse and minimizes dusting during subsequent processing.

As part of our commitment to sustainability, we proudly hold FSC® certification for our paper-based products. Moreover, our curing and non-curing resins align with environmentally conscious business practices, further emphasizing our dedication to eco-friendly solutions.

At GESSNER, quality assurance is paramount. We ensure our products are reliable, durable, and adhere to the highest quality standards. Our ultimate goal is to exceed customer expectations by delivering superior products, reinforcing GESSNER's position as a trusted partner in the engine air filter media market.

GESSNER's benefits are manifold, derived from our innovative approach and 60 years of expertise. As pioneers in introducing flame-retardant media in 1988, we set high standards in the industry. Our products successfully pass the TL848 after water soaking test for both curing and non-curing media, a requirement for OEM/OES, according to DIN 53438.

We prioritize environmental safety, offering products free of heavy metals, halogenated compounds, and any chemical compounds classified according to the VDA-list. Our media showcase excellent wet stiffness, ensuring fast curing or non-cure and resistance against water and temperature. This allows quick re-drying to prevent filter collapse.

Our offerings range from single to multi-layer media, all characterized by high stiffness in both dry and wet conditions. We further reduce environmental impact with low dusting during processing, FSC® Certification availability, and a commitment to zero emissions.

In conclusion, GESSNER stands as a leader in the filtration industry, combining technical innovation, stringent quality control, and environmental stewardship to deliver superior products that meet the most rigorous demands of today's markets.

GESSNER®´s high efficiency fuel filter medias to reach highest efficiencies and still retaining DHC: GESSNER is at the forefront of fuel filtration technology, offering high-efficiency filter media that meet the rigorous demands of modern engines. Our unique, glass-containing filter media is designed to achieve the highest possible efficiencies while retaining Dust Holding Capacity (DHC), using a special technology to avoid glass fiber shedding.

In the intricate world of engine protection,

our fuel filter media stand out for their durability and effectiveness

. Modern engines operate under high injection pressures and are often exposed to particulate contaminants in fuel. To protect these engines, GESSNER® has developed a fuel filter media that can filter out up to 99.95% of particles @4µm. This safeguarding mechanism prevents microscopic debris from causing wear or damage, thereby enhancing the longevity of the engine.

Our innovative three-layer design is key to this high efficiency. The middle layer contains micro-glass to ensure maximum filtration efficiency. It is sandwiched between a meltblown layer and a cellulose layer to prevent glass fiber shedding. This unique structure not only delivers exceptional performance but also ensures good foldability, allowing our GESSNER® material to be processed on standard equipment.

GESSNER®'s high-efficient fuel filter media revolutionize engine protection by combining top-tier filtration efficiency with practical application and safety considerations.

GESSNER's high-efficient fuel filter media offer numerous benefits, primarily due to their unique three-layer design. This design ensures maximum efficiency in fuel filtration, effectively eliminating harmful particulates and thereby extending engine life.

The inclusion of a meltblown layer enhances the Dust Holding Capacity (DHC), resulting in longer filter life and reduced maintenance costs. The sandwich structure protects the micro-glass layer from damage, preventing loss of fibers and ensuring the integrity of the filter.

Despite its advanced composition, GESSNER® material is designed for easy processing on standard equipment, thanks to the foldability of the cellulose layer. This feature, along with the design's ability to address health risks associated with glass fibers, contributes to a safer working environment.

GESSNER®'s fuel filter media provide optimal performance, offering superior value by enhancing engine protection, reducing maintenance costs, and contributing to a more sustainable future in the trucking industry.

Delpore™ calendered Meltblown nonwoven are the perfect fit for pleated or bag filters: Delpore™ calendered meltblown nonwoven serves as a key component in pleated or bag filter elements, finding extensive applications across sectors like food & beverage, oil, gas, and power generation. Its primary function is to act as an efficient filtration medium.

The meltblown technology used in Delpore™ produces very fine and highly effective filter medias. The material's intricate fiber structure and high surface area ensure exceptional particle capture, contributing to the overall performance of the filter elements.

In the food & beverage industry, it helps maintain product purity by filtering out contaminants. In oil and gas operations, Delpore™ assists in separating particulates and impurities, ensuring the smooth running of equipment and processes. For power generation, its filtration efficiency is critical in preventing damage to turbines or other machinery due to foreign particles.

Moreover, Delpore™'s calendered meltblown nonwoven material is valued for its durability and resistance to harsh conditions, making it suitable for demanding industrial applications.

In summary, Delpore™ plays a crucial role in enhancing filtration efficiency and system longevity across multiple industries, thanks to its superior filtration capabilities and durability.

The use of GESSNER’s proprietary processing techniques gives Delpore™ media a heightened dust holding capacity, reducing the required operating pressure and extending the filter life.

In the food & beverage industry, it ensures product purity by eliminating contaminants. In oil and gas operations, it aids in separating particulates and impurities, ensuring smooth functioning of equipment and processes. For power generation, its filtration efficiency is vital in preventing damage to turbines or other machinery from foreign particles

Delpore™'s calendered meltblown nonwoven material has been praised for its durability and resistance to harsh conditions, making it suitable for demanding industrial applications. It provides stability, reduces fouling, and helps prevent premature membrane failure.

Alphastar™ electrostatic nonwoven media to reach MERV 11-14 efficiencies for air filter elements: Crafted from a proprietary blend of fibers that are carded and needled into a fully homogenous material, Alphastar™ stands out for its exceptional electrostatic media designed specifically for air filtration.

Its unique triboelectric media delivers superior efficiency and lower resistance compared to similar products, acting like a magnet to capture and retain particles through electrostatic action. This ensures superior air purity, an essential feature in maintaining the safety and efficiency of various applications.

Alphastar™ offers flexibility in use, as it can be combined with various layers of material for desired product enhancements. Its high dust loading capacity and low pressure drop make it ideal for a range of applications, including vacuum cleaners' pre and post motor filters, cabin air filters, Continuous Positive Airway Pressure (CPAP) units, breathing circuitry, HVAC furnace, and industrial filters.

Alphastar™ Electrostatic Media is a key player in ensuring clean and safe air circulation in various applications, contributing to overall health, safety, and performance efficiency.

Alphastar™ Electrostatic Charged Media is a cutting-edge solution in the filtration industry, offering numerous benefits that make it perfect for achieving rates up to MERV 14. The stable electrostatic charging feature of Alphastar™ ensures efficient particle capture and retention, significantly enhancing air quality. This is especially beneficial in applications where high MERV rates are required for optimal filtration performance.

Alphastar™ boasts high-performance-to-weight ratios, making it a lightweight yet robust solution for your air filtration needs. This ensures top-notch efficiency without adding unnecessary bulk. With various needling configurations available, Alphastar™ offers versatility and customization to meet specific filtration requirements.

A unique feature of Alphastar™ is that it's fully incinerable. This environmentally friendly aspect simplifies disposal processes, reduces waste, and aligns with sustainability initiatives.

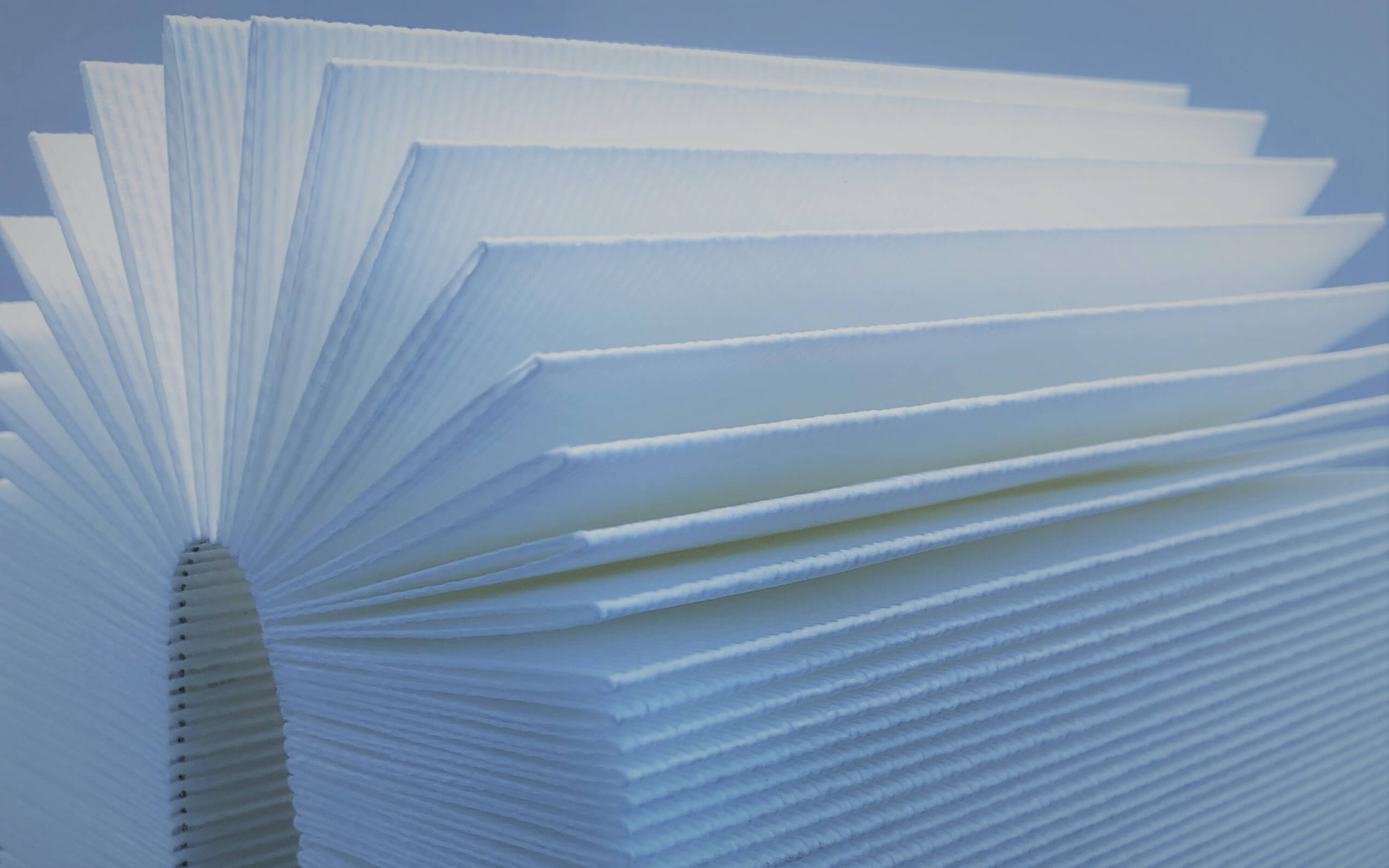

NeenahPure® highly charged Meltblown nonwoven – a self-pleatable solution for MERV 15 and beyond: NeenahPure® is GESSNER's advanced HVAC filter media portfolio offering superior solutions for air filtration. As part of this series, GESSNER presents its newest development for efficiencies MERV15 and higher. Meltblown produced with our advanced charging technology offering high efficiency and a low pressure drop is combined with a pleatable carrier to offer self-supported materials. It covers MERV efficiencies up to MERV16. The most advanced media type exceeds 99.9% under conditions of 0.3µm particle size and a face velocity of 5.3cm/s. This high efficiency ensures even the smallest airborne particles are effectively captured and removed, promoting healthier indoor environments.

Versatility is another strength of NeenahPure®, as it's suitable for both pleatable and bag filter elements and adapts to various air filtration systems. Whether for residential air purifiers, commercial HVAC systems, or industrial units, NeenahPure® delivers flexibility and performance.

The NeenahPure portfolio covers the full range of the ISO16890, EN779 and MERV standard.

NeenahPure® also excels in safety, avoiding harmful fiber shedding, and boasting a high dust holding capacity. Its favorable pressure loss and efficiency ratio ensure optimal performance and energy efficiency. Its mechanical stability underlines its reliability.

In essence, NeenahPure® combines safety, efficiency, and durability, offering a high-performing, reliable, and safe solution for optimal air filtration.

NeenahPure® filter media offers a comprehensive and high-quality solution for indoor air filtration needs. Its wide-ranging efficiencies from ePM10 50% to ePM1 80% as per ISO 16890 standards, and M5-F9 according to EN779:2012, ensure that the indoor air quality is safeguarded against pollutants, viruses, and bacteria. This contributes significantly to health protection by efficiently capturing a broad spectrum of harmful particles. NeenahPure®'s superior quality and high efficiency, exceeding 99.9%, guarantee that even the smallest airborne particles are effectively captured and removed, providing cleaner and safer indoor air. Its versatility makes it apt for both pleatable and bag filter elements, enhancing its adaptability across various filtration systems.

GESSNER®'s commitment to providing tailor-made solutions further elevates NeenahPure®'s appeal, offering customization in performance, runability, and media composition. The safety and durability of NeenahPure® are ensured through its ability to avoid harmful fiber sheddings, its exceptional mechanical stability, and flame retardancy.

Its favorable pressure loss and efficiency ratio underline NeenahPure®'s energy efficiency. By maintaining optimal performance while minimizing airflow obstruction, NeenahPure® delivers an energy-efficient solution for various applications.

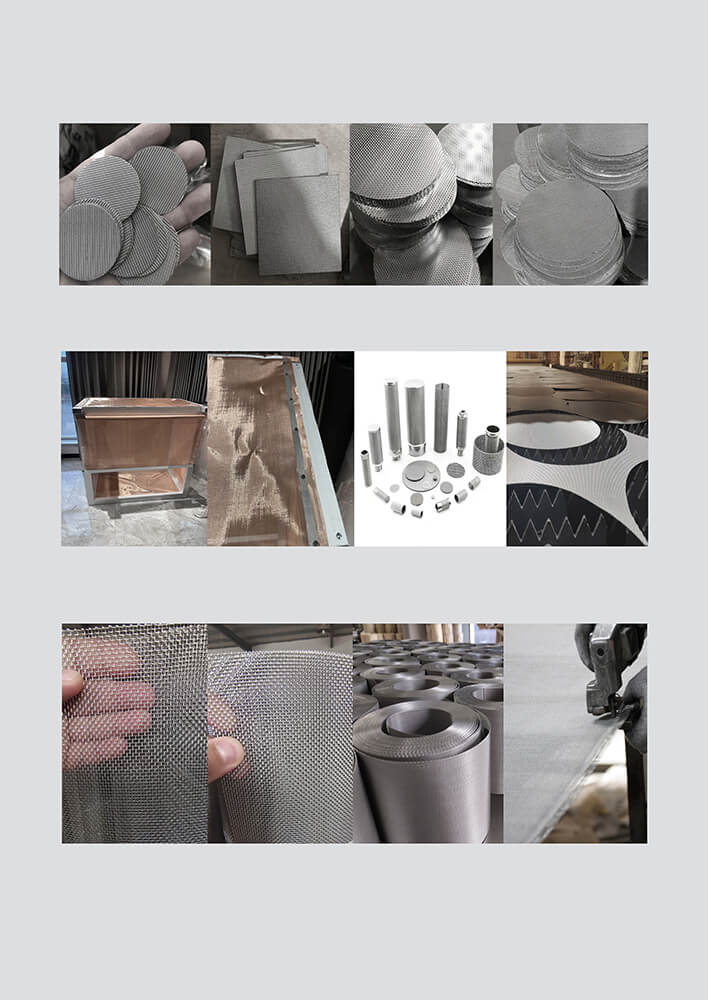

Conwed™ rigid tubes & cages and Naltex™ sleeves to protect and support filter elements: Conwed™ rigid tubes & cages and Naltex™ sleeves play pivotal roles in filtration systems across various industries.

Conwed™ extruded rigid tubes and cages, manufactured through a single-step continuous extrusion process, offer strength and consistency. They feature a square mesh netting configuration that provides superior durability compared to seamed netting tubes. These tubes are generally used to support, contain, and separate, especially in filtration applications.

On the other hand, Naltex™ extruded sleeves serve as an ideal solution for the exterior of filter elements. Made from high-performance material, these sleeves resist abrasive and corrosive elements, ensuring the integrity and efficacy of the filtration system. They offer secure fitting, thus optimizing filtration performance.

Conwed™ extruded rigid tubes and cages provide the necessary rigidity to protect delicate filtration media. The manufacturing process ensures a consistent cylindrical shape, enhancing their performance and longevity.

Depending on the choice of polymer, Naltex™ extruded sleeves exhibit different properties like temperature resistance, strength, and corrosion resistance. They are lightweight, easy to install, and available in various sizes and lengths, catering to diverse applications. By providing a reliable and efficient solution for filter element replacement, Naltex™ sleeves help minimize downtime and maintenance costs.

Therefore, both Conwed™ and Naltex™ products prove to be essential components in effective filtration systems.

About: GESSNER is a global leader in the filtration industry. We’re protecting people, machineries & the environment with our filtration solutions to ensure a better, cleaner, and healthier world.

Our highly engineered papers, films, nets, nonwovens, cores, tubes, and machined parts are designed and manufactured using natural fibers and polymers for a variety of industries and applications, such as Transportation Filtration, Water Filtration, Air Filtration, Industrial Processes, and Life Science. We provide our customers with essential components that enhance the performance of their products.

At our international production sites, GESSNER can develop and locally produce a wide range of materials to suit a variety of highly demanding applications. With continuous product development in close cooperation with our partners, we deliver tailor-made solutions suited for a variety of challenging end-user needs.